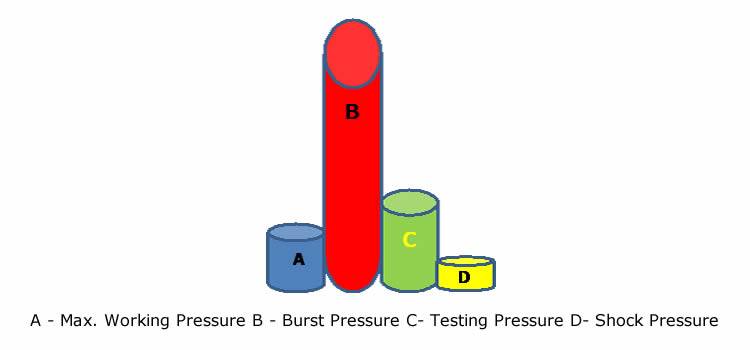

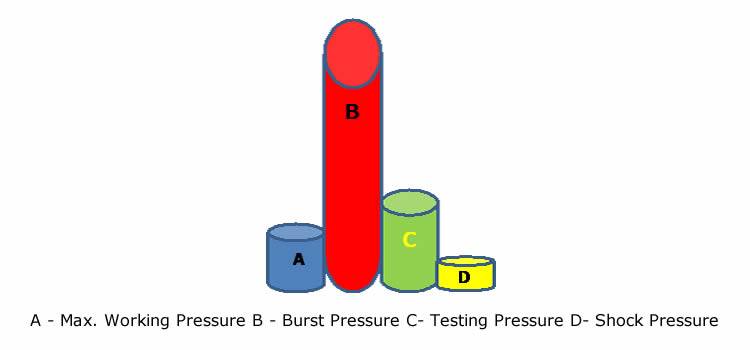

Pressure relationships for flexible metal hose

Pressure is a vital element of flexible hose selection. Perhaps you have noticed working pressure, burst pressure, test pressure and shock pressure. Are you confused about their relationships?

Maximum Working pressure – Flexible hose should be subjected to maximum working pressure. If exceeding the pressure, the potentiality of hose failure will increase accordingly.

Test Pressure – also called proof pressure, is usually 150% of maximum working pressure. Under the test pressure, no harmful deformation occurs. All our stainless steel braided metal hoses have passed through proof pressure inspection.

Burst Pressure – the pressure which causes the hose to rupture. It is usually fourfold of max. working pressure.

Shock Pressure – a harmful dynamic pressure due to fast closing valves. Peak pressures should be lower than 50% of the maximum operating pressure.

In a word, maximum working pressure defines the working pressure range and should be subjected to this value. Test pressure and burst pressure are two data which are designed to inspect the hose performance. However, shock pressure is a kind of destructive pressure which will shorten hose's cycle life expectancy.

Pressure relationships for flexible metal hose

Send Us A Message

If you need to consult the price, please contact the business department by e-mail